Thermocouple Types

- Thermocouple Type J

- Thermocouple Type K

- Thermocouple Type E

- Thermocouple Type T

- Thermocouple Type N

- Thermocouple Type B

- Thermocouple Type S

- Thermocouple Type R

- Thermocouple Characteristics

- Tolerances of Thermocouples

- Sheath Material

- Thermocouple Junctions

- Thermocouple Chart

- Thermocouple Quotation

Thermocouple References

- $ 25Donec accumn sreen amet (malesu dasere)

- $ 32Donec sit amet (amet eros do haselelu)

- $ 13Lorem ipsum dolor sit (amet dolores diolre)

- $ 12Mauris ferme qum iacu (ntum)

- $ 16Fusce feugiat (malesuada odie atweres)

- $ 12Morbi nunc (gravida roin mioliete)

- $ 23Aecenas roin dictum (lemen tristi hasellus)

- $ 14Orci ac semollor has (elluse at)

- $ 25Fusce feugiat male (seren oteres querten)

- $ 32Morbi nunc (gravida roin)

- $ 25Donec accumn (malesu dasere amet)

- $ 32Donec sit amet (amet eros do)

- $ 13Lorem ipsum dolor sit (amet dolores)

Thermocouples

Thermocouples are the most common, convenient, and versatile devices used to measure temperature. They convert units of heat into useable engineering units that serve as imput signals for process controllers and recorders. THrough selection of appropriate thermocouple wires and sheath components, thermocouples are suitable to be used in temperature ranges from

(−200 to 2316)° C (−328 to 4200)°F

Thermometrics thermocouple assemblies offer a wide variety of termination styles and mounting fittings, as well as extensive choices in sensor calibration, sheath diameter and sheath material. This section outlines the key choices needed to specify the correct Thermometrics part description for you needs.

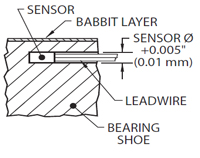

Bearing Sensor Overview

The bearings of industrial rotating equipment operate under arduous conditions - often for considerable periods of time. The most reliable indicator of bearing condition is the temperature of the metal beneath the shoe. Recognition of rising temperature can provide a warning of the breakdown of the lubricating oil film; thus allowing machine shutdown and maintenance to take place - avoiding the probable catastrophic failure of the bearing and possible damage to its mounting.

Bearing Temperature

The stabilized operating temperature of a bearing is the result of many factors. The key influences on operational temperature are bearing style, lubrication type, operational factors, environmental conditions and level of maintenance The particular bearing style (ball, roller, sleeve, etc.), the shaft mounting style (slip fit, adapter mounted, press fit, etc.) and auxiliary items (housings, seals, shields, flingers, etc.) all contribute to a final operating temperature. For a given set of application conditions, a particular bearing type will generate friction given off as heat. A typical bearing temperature rise range would be 40° to 80°F (4° to 27°C) for most industrial applications. However, a bearing temperature rise over ambient of up to a 120°F (49°C) can be observed at extreme conditions.

Oil Resistant Wire

This is a sensor wire with a fill between the wire, stainles steel braid, and outer jacket. This fill can extend along the entire length of the cable, or a specified portion. The outside of the cable can be sealed with a fitting as well.

Bearing Sensor Installation

Bond with epoxy inside bearing shoe. Locate near the babbitt face for most accurate readings. For specific case style installations please click below.

diolor porta hasellus atre sreen mioliste port hasellus amet.

Adipiscing seren ame tdollor rerit at muris fusce suscipit ociis aparturient ont nascetur ridicsrem ipsum olor sit amet cocing vestienean nonum.